The companies that succeed in overcoming today’s supply chain issues will be those willing to lead with flexibility, innovation, and collaborative approaches to problem-solving. They’ll also embrace data and look for supply chain management software solutions to find ways to actually use it.

These are the biggest contributing factors you’ll hear about in our April Huddle, featuring guests from Barcoding’s technology partner, Honeywell Productivity Solutions and Services (PSS). Honeywell PSS creates mobile computers, printers, and data capture devices that improve worker productivity.

What will tomorrow’s solutions look like? One key lesson learned over the past two years is that solutions don’t depend solely on innovative thinking; they need to be able to be built—and that depends on what’s available, in a literal, supply chain sense. From raw materials to components, things are complicated right now.

That’s why innovating to solve today’s problems means picking up the pace and bringing future solutions forward into today’s challenging industrial landscape. At times, that means collaborating in new ways with partners and service providers to overcome problems more efficiently, and save time as a team.

April Huddle participants include:

- Jody Costa, VP of Marketing & Strategic Partnerships, Barcoding

- Taylor Smith, Chief Technology Officer, Honeywell Productivity Solutions and Services (PSS)

- GW Hall, Sr. Channel Business Manager, Honeywell PSS

As you listen to this month’s Huddle, you might be surprised at where these experts see the best applications for automation. You may be even more surprised to hear how a leader in productivity technologies thinks about applying tech to solve operational issues (hint: it doesn’t start with a technology focus!)

Flexibility Helps Bring the Future Into the Now

Futurists may get a lot of air time talking about the big ideas and new technologies coming down the pike, but in times like these, with sourcing and supply chain obstacles obstructing productivity in just about every direction.

Taylor sees effective CTOs leading by bringing together global, cross-functional teams from sourcing, supply chain, and engineering, and taking a three-pronged approach to solving problems associated with hard-to-get (or outright unavailable) SKUs:

- Leveraging all of an enterprise’s sourcing relationships

- Redesigning products to take advantage of what is available

- Working closely with sales reps and partners like Barcoding to identify appropriate and acceptable SKU substitutes for customers

One major challenge to redesigns is remaining mindful, in the face of shortages and sourcing problems, of the three Fs: form, fit, and function. In order for a new, innovative solution to work for a customer, these three factors need to remain—and if any of the three Fs must change, communication is critical with new SKU releases to make it clear what is different and how customers can make it work for them. This is how shared disruptions can become shared innovations.

Given current long lead times, flexibility and collaboration between customers and solutions providers are a must. Urgency can’t always change a lead time, but when customers are flexible and open to conversations about alternatives, that’s when providers can bring forward new solutions that can work for their applications. The shared learning that comes from both sides of the collaboration is what’s paving the path toward the future.

What’s Ahead and Exciting in AIDC

It can be tough to get excited about the future when everyone’s putting out sourcing and supply chain fires while simultaneously addressing labor shortages and energy cost increases, but Taylor sees exactly those challenges as opportunities for near-term improvements that companies should keep an eye out for.

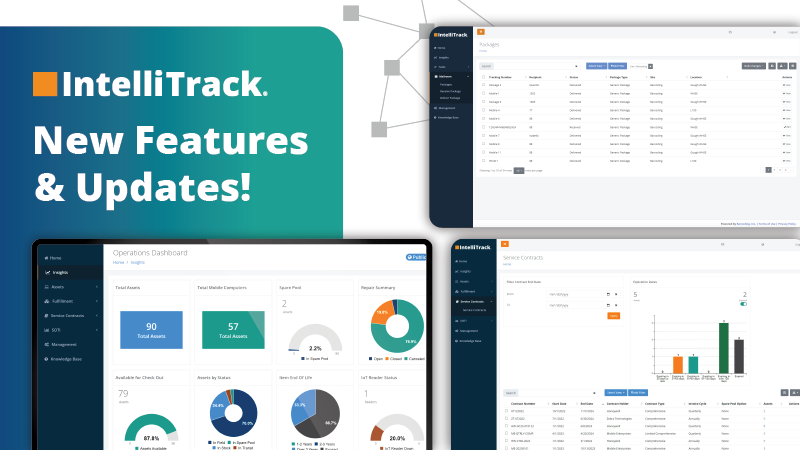

He points to productivity software innovations coming soon, designed to help organizations address the 15-20% of employees’ work time that’s actually unplanned and unstructured—the troubleshooting, problem-solving, and responding to needs as they arise. Given current labor shortages, the efficiency of that 15-20% of workers’ time can make an enormous difference to an enterprise organization.

It’s also key to understand that, even the most technologically advanced companies aren’t anticipating a future free of workers. Instead, the approach is all about using data and technology to better realize workers’ potential, automate the mundane and repetitive tasks, and make work better for people.

In a forward-looking scenario, that means digitizing every task set, to get a full digital view and analytics, to really understand what happens day in and out on a production floor.

For today, helping customers means meeting them where they are and helping them move forward in their own digital transformation. The spectrum runs from paper-based inventory management systems to digital inventory software with a scanner, to inventory management software solutions that incorporate automation.

Solutions providers need to look at a company’s individual workflows for receiving, packing and shipping, replenishment and more, to discover their individual pain points and help usher in the most useful automation for their situation. One size definitely does not fit all.

On the Wider Horizon

Taylor see’s today’s focus on digitizing work and collecting the data as a crucial step toward what we’ll see in the next decade or so.

Other key developments, like improved connectivity with 5G infrastructure and Wi-Fi 6, have the potential to bring forward capabilities that have stumped businesses for decades, like advanced indoor locationing, greater use of wearables, augmented or virtual reality where use cases warrant, and faster, more robust data collection and analysis.

Of course, all that data can also translate into more effective automation, and robotics are an exciting element of future technologies. The different forms robotics can take in operations vary widely. Taylor sees experts like Honeywell as integral to incorporating the right types of robotics, automation, and/or autonomously operated equipment into a customer’s workflow … and that relies on the right data and the software to integrate it all.

Collaborative Partnerships are Key Investments

Taylor points out that Honeywell, as a major enterprise in the space, not only monitors but also provides critical support to tech innovation by investing in maturing startups that may make strong tech partners in the future. If the CTO of an organization as large and diversified as Honeywell says not to expect to go it alone, that’s pretty sound advice.

One example Taylor points to is Honeywell’s FarEye software. This investment has enabled Honeywell to bring advanced last mile solutions to customers while also getting an inside view of successful startups that quickly go to market and scale.

So, where should companies invest their time to research and learn in the AIDC space? According to Taylor, technology comes second. (Maybe even third.) First, scrutinize operations to identify bottlenecks and root causes—by actually going out and spending time on the floor, with the people tasked to do the work. Until you really understand the problem you’re trying to solve, it doesn’t make sense to explore which technologies might solve it.

Watch the recap of the April Huddle, below!

Find the Right Partner for a Smooth Transition

Choosing the right solutions to your operational challenges means finding the right partner that can help you dig in and understand the problem—and connect you with solutions providers that are already blazing the trail to a data-driven future. Learn more about how to evaluate providers and choose the best fit for your business with our free guide, 12 Tips for Selecting the Right Supply Chain Technology Partner. Just click below to claim your copy now.